This article was originally published back in 2019 on the HVAC School website.

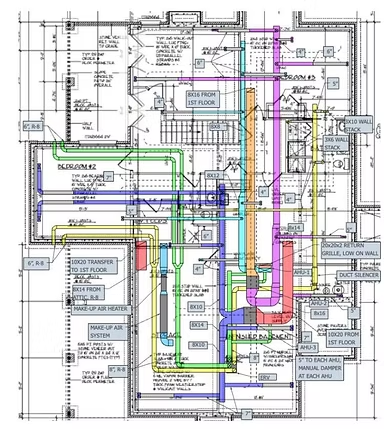

These are some fundamentals for designing and installing duct systems that I’ve learned over the years. Included are links to some great resources if you choose to dig a little deeper.

#1. Lower the air velocity, and static pressure will follow.

The total equivalent lengths (TEL) for fittings in Manual D are based on 900 feet per minute air velocity. When the velocity is lowered, friction is lowered; hence, TEL is lowered. This means you can “get away” with some lower-performing fittings if the velocity is low.

ACCA’s Manual D appendix 15 conclusion states, “There are scores of things to worry about when designing and installing a comfort system. Low velocity through a duct system is not one of them.”

John Semmelhack proved this to me when I installed one of his designs. We conditioned a large area with a small low static ducted mini-split without any “high performance” fittings. Basically, he increased the duct sizes to above what’s “normal” to make sure velocity doesn’t go above a set value. (We’re not talking about increasing the duct sizes a lot, one or two sizes bigger than you’re used to.) The total external static pressure was 0.17” WC. When we commissioned the system, every register delivered design airflow.

This article by Allison Bailes goes into way more detail on the topic: https:// www.energyvanguard.com/blog/is-low-velocity-bad-air-flow-ducts.

#2. The largest “duct” in the house is the house itself. What connects the air coming out of the supply registers to the air going into the return grille? The house. It’s a big duct—another reason why it’s difficult to provide comfort solutions without looking at the house as a system. In a battle between HVAC and a leaky, poorly insulated house, the house always wins. (And the people lose.) This article by David Richardson is one reason I started to take the “house is a system” approach: https://www.achrnews.com/articles/126814-the-building-side-of-the-ductsyste.

#3. The closer the duct is to the blower, the more important it is. This is where pressures in the duct system are the highest. Low-performance fittings create higher pressure drops (compared to lower-pressure parts of the duct system). The “system effect” can come into play, and any duct leakage will be intensified. It’s important to have larger, high-performance fittings, with as much of a straight section as possible entering and leaving the equipment. I touch on this again in rule #13.

#4. Return location doesn’t matter as long as pressure imbalances aren’t created. “Add a return” is the go-to move for some to solve comfort issues. But if the equipment is moving the design airflow, and the room does not have a pressure imbalance, adding a return will not change anything. Supply registers condition the air and create room air currents; returns don’t do that. What’s important is that return air has a free path back to the return grille, not the grille’s location.

#5. Air is a fluid; ducts should not leak. Duct leaks in unconditioned spaces will cause outside air to enter into the conditioned space. This is an energy and IAQ penalty; I’ve heard Nate Adams call it the “double whammy” because you basically pay for it twice. (Once to condition the air, then again to re-condition the outside air.) More on duct leakage in this tech tip: https://www.hvacrschool.com/duct-leakage-canbe-costly/). Even if the ducts are in a conditioned space, they still shouldn’t leak. Having an air leak in unintended spaces is not efficient or high-performance. You will not be able to match room-by-room design airflow if x amount of air is leaking behind walls. This study by Comfort Institute (owned by Aeroseal) was conducted to prove leaky ducts in conditioned space matter: https://comfortinstitute.org/blog/healthy-home/research-ductsealing-whole-house-leakage/.

#6. Install balancing dampers to regulate airflow. Without balancing dampers, it’s difficult to balance airflow. Some rely on design software to create a “self-balancing” system. Personally, I haven’t seen this work other than accidentally. Our preference is to use registers with opposable blade dampers. This makes balancing a lot faster and easier. On top of that, they are always accessible, and they don’t leak air as typical takeoff manual dampers do.

#7. Increase filter surface area to lower pressure drop. When designing to a static pressure of 0.50 inches water column (in.w.c.), a good rule of thumb is to keep the pressure drop across the air filter at or below 0.10in.w.c. This will not happen with a standard 1” filter if you plan on using anything other than a see-through “rock-catcher.” If you want a high-performance filter (you should), the 4” media type have low-pressure drops, but you might have to use two for anything above a 3-ton. Our preference is 2” filter grilles with MERV 13 filters. They’re easy to accommodate on new construction and retrofit with multiple returns. Keep in mind that the MERV rating of filters is typically at a low velocity, say, 300 FPM. The filter performance drops when velocity is increased. Allison Bailes (yes, him again) of Energy Vanguard recently blogged on this topic: https:// www.energyvanguard.com/blog/path-low-pressure-drop-across-high-merv-filter.

#8. Avoid installing ducts in unconditioned spaces. Vented attics are the worst possible place for the ducts. It’s the hottest part of the house in the summer and the coldest in the winter. Ducts in vented attics come with a large energy penalty. Vented crawl spaces do not have as heavy of an energy penalty, but because of high humidity, they present other challenges. Supply duct leakage will cause outside air infiltration due to depressurizing the living space. Any return leakage will directly bring in attic or crawl space air. Here’s a great article from one of the best building science resources: https:// www.buildingscience.com/documents/insights/bsi-074-duct-dynasty.

#9. Select registers with enough throw to provide adequate air mixing. This helps provide even room temperatures, prevents stratification, and reduces the number of registers needed per square foot. We use many curved blade ceiling registers located close to an interior wall, pointed toward the exterior. In addition to good air mixing, interior high wall or ceiling register placement also uses fewer materials when compared to an exterior location. Simple, small duct systems cost less, leak less, and have less thermal transfer. This is one of my favorite free duct design resources: https://www.nrel.gov/docs/fy12osti/53352.pdf.

#10. Test your duct system to verify the design. Feedback may be the single most important thing when it comes to your process and improving it. Whether it’s from a duct leakage test (even when it’s not required) or measuring airflow, feedback accelerates the learning process and allows you to make adjustments to your design on the fly.

#11. Flex duct is high-performance if installed straight and tight. Don’t believe me? Try it. Because of rule #10, I know this to be true. Yes, I probably could have linked Energy Vanguard to every rule: https:// www.energyvanguard.com/blog/57709/How-to-Install-Flex-Duct-Properly.

#12. Don’t blow air on people. In my opinion, this is why heat pumps get a bad rap. It’s not comfortable having 85° air blowing on you. At the same time, that 85° air may be enough to maintain a 70° room temperature. Keep this in mind when selecting register type and location.

#13. Use elbows with radius throats or turning vanes. In ACCA’s Manual D, Appendix 3, you will see how much of an impact radius throats and turning vanes have compared to square throats and elbows without turning vanes. You will also see that radius heel vs. square heel makes little difference. Piggybacking on rule #3, high-efficiency fittings have a greater impact the closer they are to the equipment. When doing a retrofit, I will often install turning vanes in the existing fittings that are close to the equipment. This is a good way to make measurable improvements without reinventing the wheel.

#14. Design and build quiet duct systems. Noise can come from several sources: vibration, turbulence, high velocity, and equipment. Depending on the type of equipment and its orientation, there are several ways to isolate it from the structure to reduce vibrations. I always use canvas connectors as close to the equipment as possible to support ducts while being decoupled from the equipment. Vibration pads under the equipment help if it is installed on a platform or stand. Hanging equipment using spring or neoprene isolators provides better isolation but is more time-consuming and costly.

Air noise from high velocity and turbulence can be reduced by fittings with sweeping turns and lowering the velocity. In addition to that, silencers (such as Fantech’s LD line) and flexible ducts are effective. Some use an acoustical liner (which works), but we choose not to because of IAQ concerns. (Potential deterioration and releasing fiberglass into the airstream also tends to promote mold growth on the supply side). One technique for addressing equipment noise is reducing line-of-site. Most of the time, you can do this with a few turns in the ducts between the equipment and any registers and grilles.